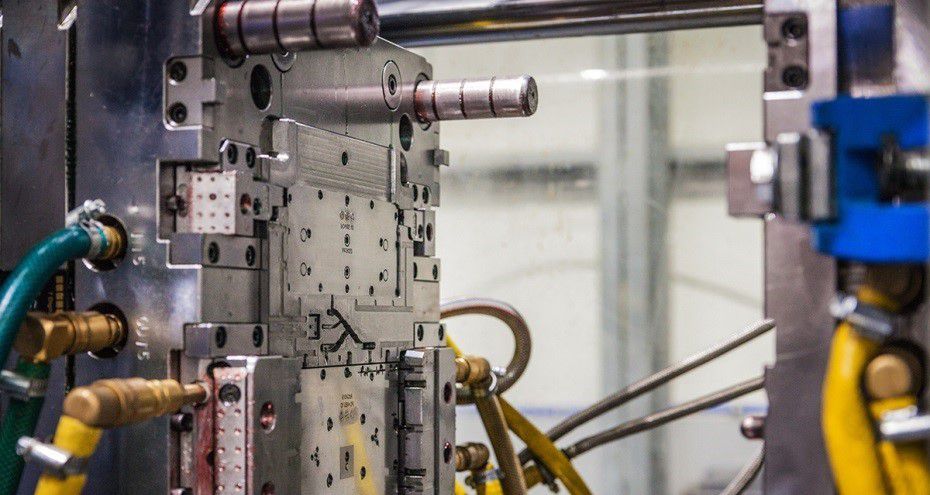

Injection molding

We provide the best cost effective and high quality injection moldings.

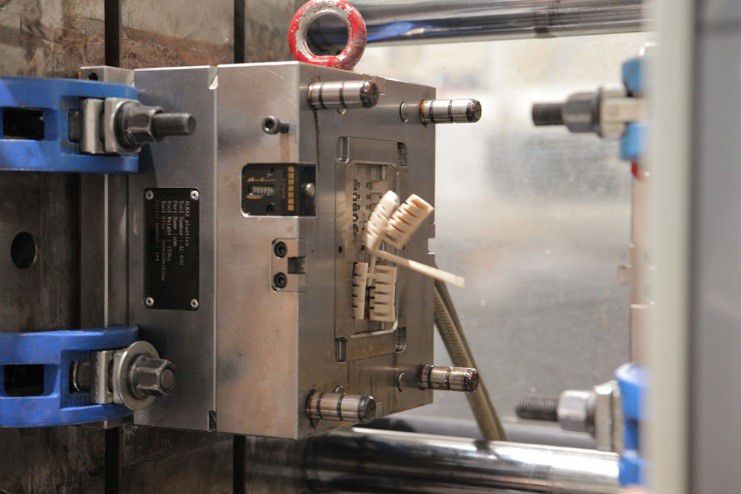

Injection molding is an excellent way to bring out the best in plastics. It is universally used to make complex, finished parts, often in a single step, economically, precisely and with little waste.

If you need injection molded plastic parts, custom injection molded parts, assembled plastic injection molded parts or custom injection molded tooling you’ve come to the right place.

ALKAZ Plastics company provides engineering services, in house mold making, all secondary operations, turnkey contract manufacturing, 80 ton to 1200 ton molding machines and product assembly.

From the highly complex to the straightforward components can be molded in a variety of thermoplastic materials, including Nylon, Noryl, LCP, Polyester, Polycarbonate, Polyethylene, Polypropylene, ABS, Acetal, TPES, PES and PTFE, and where practical the use of reprocessed materials.

We are also able to color these materials if required by liquid, powder or master batch methods. Light assembly work including: ultra-sonic welding, pad printing and hot foil stamping can also be quoted for in addition to the basic molding production.

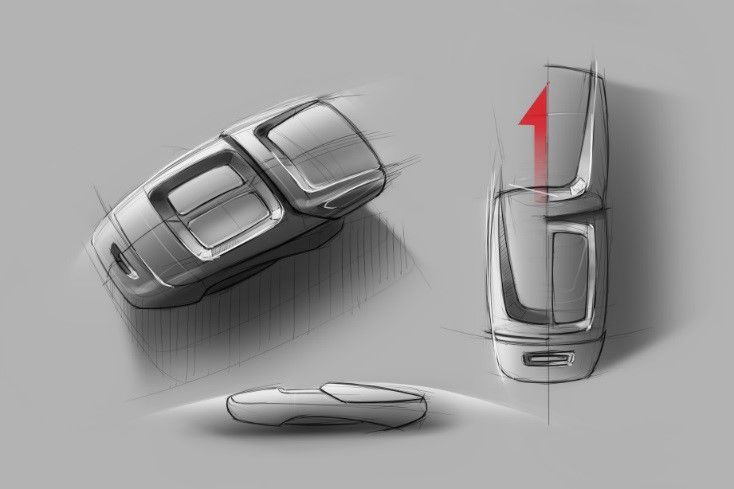

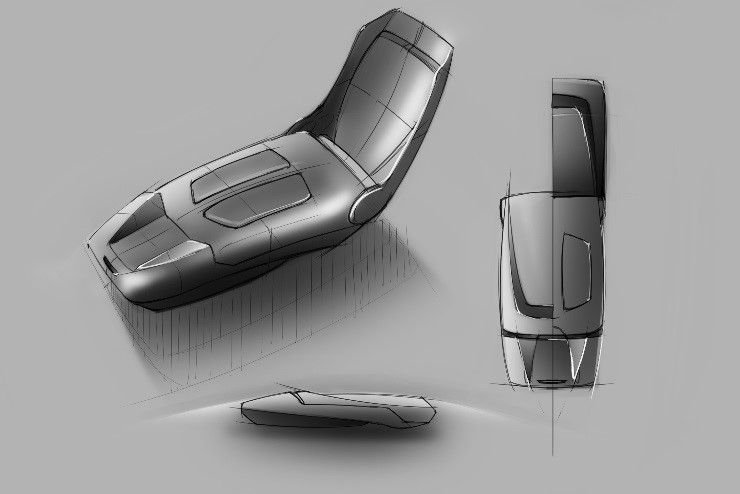

Plastic molding material selection.